1.Our capsule printing service is available for both Axial and Rotational Printing 2.Allergen Free, Preservative Free, Non–GMO, Gluten free, Non-irradiation. 3.Manufactured in accordance with NSF c-GMP / BRCGS guidelines 4.Odorless and tasteless. Easy to swallow 5.Excellence filling performance on both high-speed and semi-automatic capsule filling machine 6.he entire manufacturing process consists of over twenty checkpoints, ensuring all stages of the manufacturing process compliant with GMP standards 7.YQ printing empty hard capsule has a wide range of applications for pharmaceutical and nutraceuticals industry.

1.Our capsule printing service is available for both Axial and Rotational Printing 2.Allergen Free, Preservative Free, Non–GMO, Gluten free, Non-irradiation. 3.Manufactured in accordance with NSF c-GMP / BRCGS guidelines 4.Odorless and tasteless. Easy to swallow 5.Excellence filling performance on both high-speed and semi-automatic capsule filling machine 6.he entire manufacturing process consists of over twenty checkpoints, ensuring all stages of the manufacturing process compliant with GMP standards 7.YQ printing empty hard capsule has a wide range of applications for pharmaceutical and nutraceuticals industry. NSF c-GMP, BRCGS, FDA, ISO9001, ISO14001, ISO45001, KOSHER, HALAL, DMF RegistrationYiqing printing capsules are always made from the best raw material available. Our mission is to manufacture and market the high quality capsules derived from the best material nature has to offer. Current regulations require product identification for pharmaceutical oral dosage forms. In the health nutrition field, there is an increasing demand for product differentiation. Our capsule printing service is available for both Axial and Rotational Printing using FDA approved ink. The selections of ink colors include black, white, red, blue, green and gray. Yiqing unique printing capsules are results of our relentless pursuit for natural products via science and innovations. All capsules are natural, safe for long term human consumption, scientifically sound, unique and innovative in nature and are Bright‘s gift to the world through the collective aspirations.

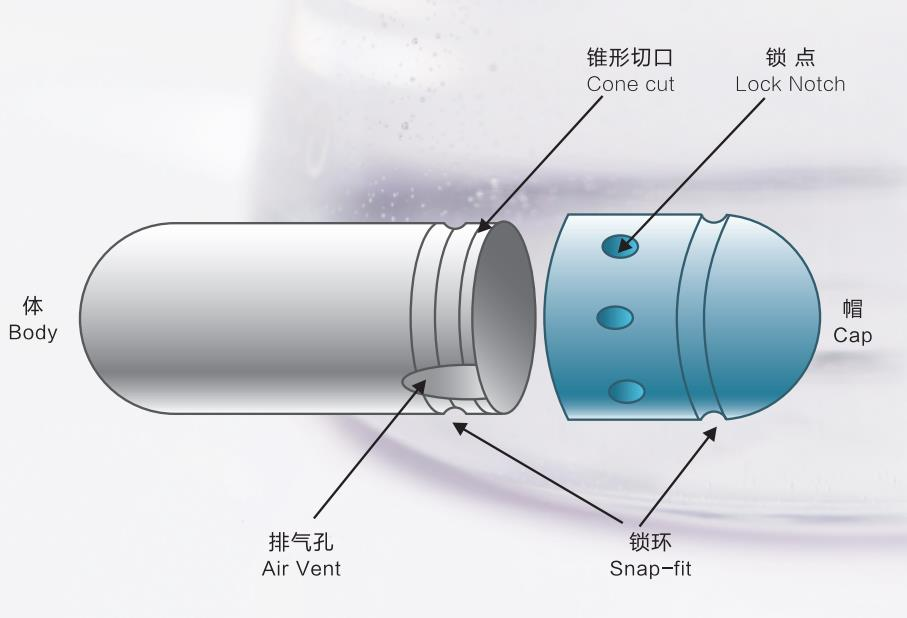

NSF c-GMP, BRCGS, FDA, ISO9001, ISO14001, ISO45001, KOSHER, HALAL, DMF RegistrationYiqing printing capsules are always made from the best raw material available. Our mission is to manufacture and market the high quality capsules derived from the best material nature has to offer. Current regulations require product identification for pharmaceutical oral dosage forms. In the health nutrition field, there is an increasing demand for product differentiation. Our capsule printing service is available for both Axial and Rotational Printing using FDA approved ink. The selections of ink colors include black, white, red, blue, green and gray. Yiqing unique printing capsules are results of our relentless pursuit for natural products via science and innovations. All capsules are natural, safe for long term human consumption, scientifically sound, unique and innovative in nature and are Bright‘s gift to the world through the collective aspirations. End of Cap It is the main part bearing closing pressure during locking motion. Its thickness must bear closing force of the filling machine to prevent dent. Hemispherical End This section also needs to bear closing pressure during locking motion. Body Thickness Thickness must be within specifications for enabling to perform smoothly during filling process and to have a close fit between the walls of cap and body. Edges Smoothness of cutting edges can affect the capsule filling performance. Tapered Rim The tapered rim design on the body allows for telescope-free encapsulation, especially on the high speed capsule filling machines. Locking Rings They are designed to be close-fitting during Locked status and to prevent from separation or content leakage. Dimples They are designed to gently engage with indented ring of the body during Pre-Locked status. Air Vents They are designed to release the compressed air inside capsule occurred during filling process.The origin of raw materials is approved as “Generally Recognized as Safe” (GRAS). FDA approved ink. Hence the quality of YQ printed empty hard capsules are safe and reliable. Consistent quality. 99.99% machine-ability on all makes of encapsulation machines. The quality control of raw and auxiliary materials is higher than the national standard Persisting in making high-quality capsules is the core of our quality value. We always adhered to the business philosophy of good faith, managed in accordance with the GMP standard of medicines, and established a comprehensive quality management system to implement the entire process of quality control of raw materials and auxiliary materials procurement, acceptance, product production process, storage and transportation, and customer service.

End of Cap It is the main part bearing closing pressure during locking motion. Its thickness must bear closing force of the filling machine to prevent dent. Hemispherical End This section also needs to bear closing pressure during locking motion. Body Thickness Thickness must be within specifications for enabling to perform smoothly during filling process and to have a close fit between the walls of cap and body. Edges Smoothness of cutting edges can affect the capsule filling performance. Tapered Rim The tapered rim design on the body allows for telescope-free encapsulation, especially on the high speed capsule filling machines. Locking Rings They are designed to be close-fitting during Locked status and to prevent from separation or content leakage. Dimples They are designed to gently engage with indented ring of the body during Pre-Locked status. Air Vents They are designed to release the compressed air inside capsule occurred during filling process.The origin of raw materials is approved as “Generally Recognized as Safe” (GRAS). FDA approved ink. Hence the quality of YQ printed empty hard capsules are safe and reliable. Consistent quality. 99.99% machine-ability on all makes of encapsulation machines. The quality control of raw and auxiliary materials is higher than the national standard Persisting in making high-quality capsules is the core of our quality value. We always adhered to the business philosophy of good faith, managed in accordance with the GMP standard of medicines, and established a comprehensive quality management system to implement the entire process of quality control of raw materials and auxiliary materials procurement, acceptance, product production process, storage and transportation, and customer service.